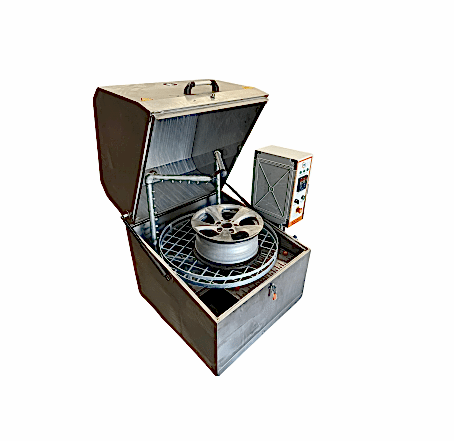

TORNADO RIM ELECTROSTATIC POWDER COATING OVEN

The TORNADO Wheel Electrostatic Powder Coating Oven

is an industrial oven used to ensure that electrostatic powder coating, once applied to wheels, adheres to the surface permanently and durably. The powder coating process offers a more environmentally friendly and robust finish compared to liquid paint. The oven facilitates the melting of the applied powder coat at a specific temperature (typically between 180-220°C), allowing it to bond to the wheel's surface, and then curing it to harden. This curing process guarantees that the paint forms a homogeneous, smooth, and highly resistant surface on the wheel, capable of withstanding impacts, scratches, and chemicals. The oven typically features precise temperature control and an insulated interior volume to ensure excellent heat distribution. The TORNADO Wheel Electrostatic Powder Coating Oven is a critical piece of equipment in wheel restoration and manufacturing processes, directly influencing the quality and lifespan of the final paint finish.

Powder Coating Oven |

It can reach up to 250 °C |

Powder Coating Oven inner dimension 1200x1200x1500mm |

Heating system: Thermoblock, closed air circulation, direct heating |

Heating capacity: 18 kW |

Circulation fan: 0.75 kw |

Electrical material: Siemens or Schneider |

Insulation: 150mm Mineral Wool |

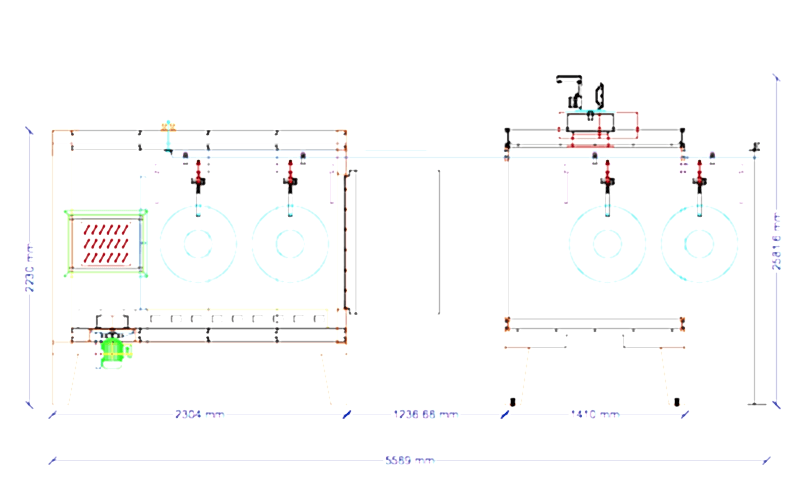

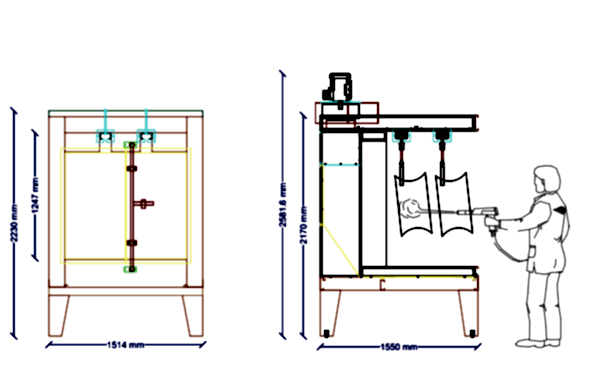

Powder Coating Bootht with 3 Filters |

Powder Coating Gun |

Rail and Hanger Apparatus |