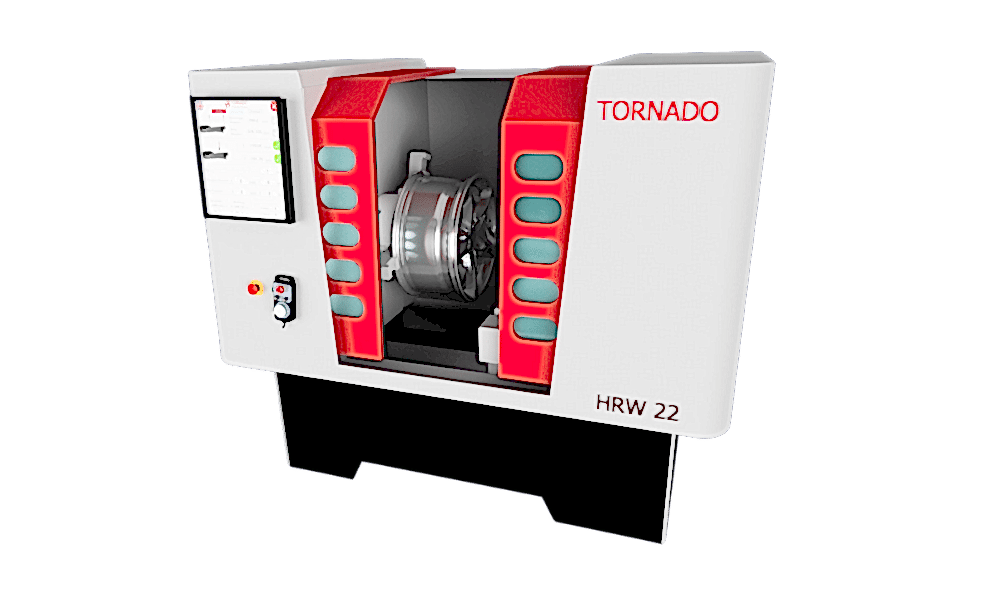

TORNADO HRW 22 HORIZONTAL CNC DIAMOND CUT

The TORNADO HRW 22 Horizontal CNC Wheel Lathe Machine

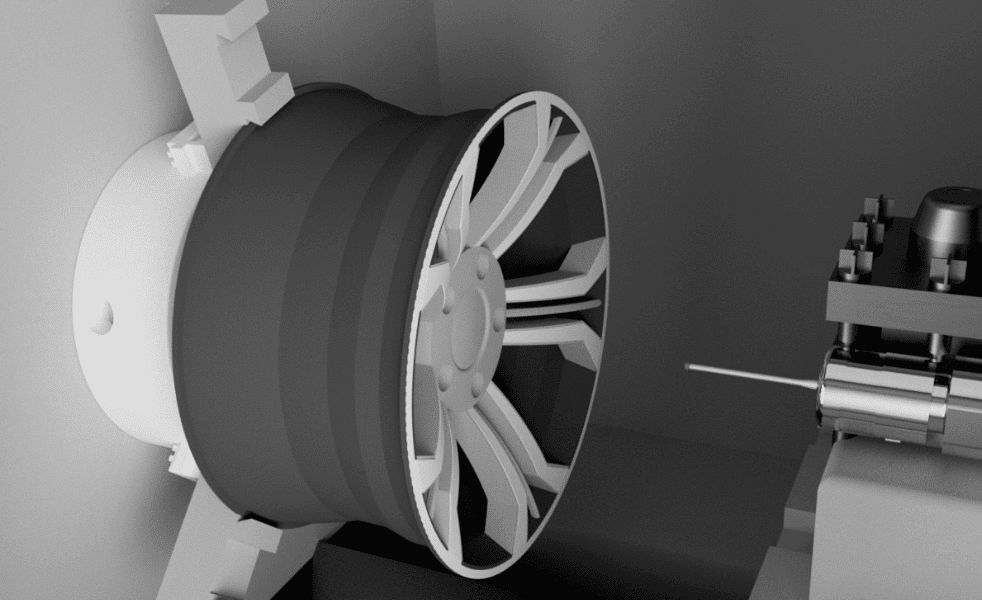

is an advanced piece of equipment specifically designed to precisely restore the surfaces of damaged alloy wheels to their original, factory-grade quality. Unlike traditional lathes, this machine can effortlessly work on complex and contoured wheel surfaces. Its operation is incredibly precise: first, a highly sensitive ruby probe scans the wheel's surface, capturing its exact form with an astonishing accuracy of 0.002 mm, typically within 1 to 4 minutes. The machine's internal software then processes this data to determine the optimal machining path. Following this, a diamond tip removes a thin layer of material, typically 0.2 mm, from the wheel's surface. If needed, this process can be repeated in additional steps of 0.1 mm or 0.2 mm. The result is a brilliantly polished surface that looks just like new. The TORNADO HRW 22 can handle wheels up to 22 inches in diameter and features a detailed tracking system that saves information such as the wheel's license plate, customer name, and a photo taken by its built-in camera. These capabilities make it a valuable investment for wheel repair shops and service centers, significantly boosting both efficiency and precision.

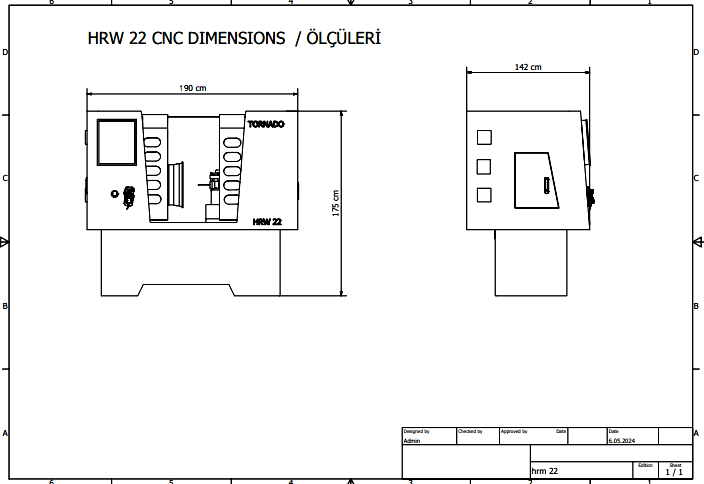

| MODEL | HRW 22 |

| MAX RIM DIAMETER | 22'' |

| WORKING SPACE | X:880 mm Y:390 mm |

| MAIN MOTOR | 4 KW |

| MOTOR SPEED | 0-1200 RPM |

| CONTROL SYSTEM | MOTION CONTROLLER |

| SCREEN | 15’’ TOUCH SCREEN |

| AXIS MOTOR | AC SERVO MOTOR |

| RIM MEASUREMENT SYSTEM | RUBY TOUCH PROBE |

| MEASUREMENT PRECISION | 0.002 mm |

| INSTALLED POWER | 380 V 3 PHASE |

| NET DIMENSION | 1900x1450x1800 mm |

| NET WEIGHT | 1030 KG |